Requires a Professional Account

Wastewater Treatment and Pollution Prevention

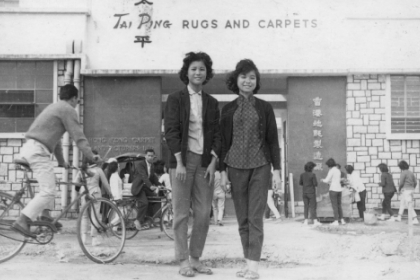

The Tai Ping artisan workshop is a zero pollutant discharge facility where 100% of water needs are met through recycling and rainwater harvesting. The wastewater treatment plant incorporates settlement, filtration, ultra-filtration, aeration and flocculation, chemical and biological treatments and reverse-osmosis which remove all colour and pollutants. The resulting clean water is upcycled for use in yarn dyeing, bathrooms, factory cooling equipment and irrigation systems to water the grounds and outdoor employee rest areas.

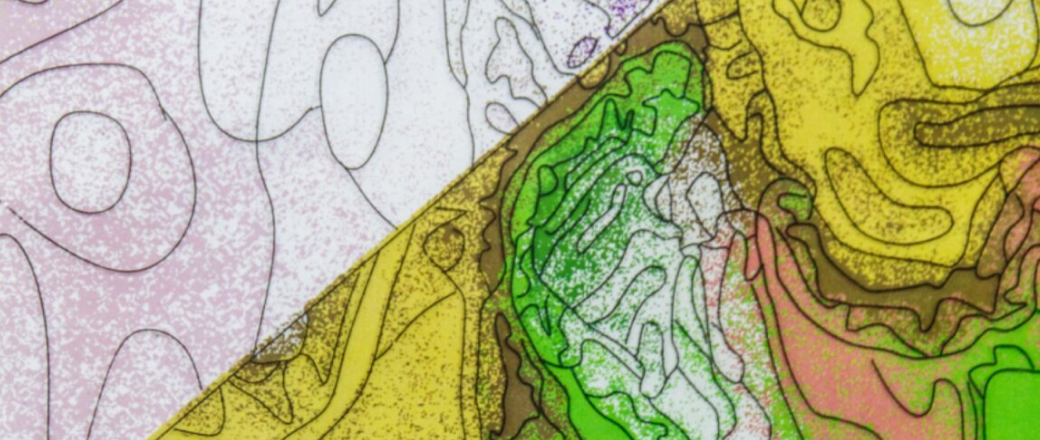

Tai Ping’s fully-integrated dyeing process results in better quality yarns and shorter supply times with industry-leading colour management and colour dye performance. All colorants used in dyeing comply withThe Ecological and Toxicological Association of Dyes (ETAD) recommendations (reduction of heavy metal impurities in organic dyestuffs and pigment preparations), and EU Directive 2002/61/EC (prohibits the use of Azo dyes containing 22 aryl amines).

Recycling and Waste Reduction

Reduce

Tai Ping follows a continuous improvement program for waste reduction which starts by controlling the weight and length of input materials and standardising the method of carpet fabrication. This resulted in a 30% reduction in input material weight and resulting output waste over the past eight years.

Reuse

Offcuts (yarn and other materials) are saved and either reused in manufacturing through re-dyeing, or used on other projects. In 2019, the workshop achieved an average yarn utilisation rate of 75.2%.

Recycle

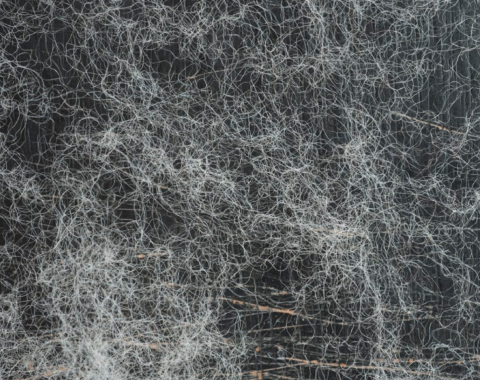

Any materials not reused or recycled are donated or sold as raw materials to selected partners or innovators, used in a variety of ways such as for bedding materials and flexible outdoor sports surfaces, or for art installations such as sculptures and more. For example, in 2019 Tai Ping partnered with Design Trust Futures Studio in Hong Kong on a year-long initiative titled Heritage is Innovation which involved the upcycling of yarn scraps repurposed to make decorative vases.

Quality and Durability

Tai Ping commitment to quality demands using the finest natural materials. Fibres used include pure wool, silk, flax and linen, which are 100% biodegradable and sourced exclusively from ethical, reputable suppliers. Wool, silk, flax and linen are rapidly renewable resources. Wool, with its impressive ‘green’ qualities, is non-off-gassing, and removes pollutants from other elements of the indoor environment over periods as long as 30 years.

With an active research and development team monitoring technological advancements in yarn preparation, dyeing, tufting and overall product construction, Tai Ping leads the industry in extending product lifespan and reducing environmental impact.

Vertical Integration

Tai Ping’s artisan workshop is a wholly-owned facility that is vertically integrated for maximum process control and greater independence from supply chain uncertainties. From design to installation, Tai Ping provide full transparency and confidence around environmental credentials and employee welfare.

The in-house management and execution of materials testing, design, sampling, template production, yarn preparation, dyeing, tufting, latexing and finishing, ensures total quality control and full validation of the processes and working conditions.

Sustainable Factory Architecture

Designed by Paris-based Sandrolini Architecture, Tai Ping’s state-of-the-art manufacturing workshop in Xiamen, China features environmentally-friendly elements that minimise energy consumption and maximise the use of natural light and ventilation.

Evaporative cooling systems and north facing ventilation methods reduce energy consumption. The heating, ventilation and air conditioning (HVAC) system is limited to critical areas (dyestuff storage, dyeing and the control room), while other work areas feature air circulating fans, the use of water and plants, natural air vents, projected shade and atrium spaces that draw in fresh air. In addition, natural light and energy-efficient LED lighting systems, plus strict machinery scheduling reduce energy consumption.

Ethical and Sustainable Value Chain Partners

Tai Ping has longstanding partnerships with preferred yarn suppliers audited regularly on their material supply credentials. Tai Ping verifies the source of all incoming materials and the ethical standards of all approved suppliers.

Based on external auditing of Tai Ping's ethical sourcing, global renown luxury brands register Tai Ping as an approved supplier.

Carpet Versus Other Flooring Options

Beyond its obvious aesthetic values, carpet offers many benefits that cannot be found in other floor covering options. For examples, carpet emits less volatile organic compounds (VOCs), and provide cushioning, anti-slip, acoustic and thermal benefits to the home. In addition, properly maintained carpets trap allergen and allergy sufferers and are therefore beneficial to asthma and allergy sufferers.

Natural vs. Recycled Materials

Tai Ping sources predominantly natural sustainable fibres such as wool, silk, cashmere, cotton, jute and flax, which remain the source of economic vibrancy for millions of people including small-scale processors and farmers. These natural fibres are renewable, recyclable, naturally decompose, have anti-soiling properties and are flame resistance.

Synthetic fibres by comparison are made from non-renewable fossil fuels, produce dangerous emissions and consume significant amounts of energy, water and chemicals at the production stage, do not decompose, shed microfibres and are flammable.

Tai Ping strives to continue making environmentally-informed decisions regarding the use of recycled components in the manufacturing process.

Superior Wool from New Zealand for Luxurious, Durable, and Sustainable Carpets

New Zealand wool is integral to Tai Ping's commitment to excellence, offering durability, longevity, and ease of maintenance. It consistently delivers pure whites and vibrant colours, including pastels and smooth tonal transitions.

Tai Ping sources wool from various New Zealand sheep breeds, including Romney, Perendale, and Merino, to ensure high-quality fibres. Romney wool is valued for its durability, softness, and natural luster, while Perendale wool balances softness and sturdiness, retaining shape and texture over time. Merino wool is renowned for its exceptional softness, fine texture, and vibrant colours, preferred for felted-wool yarns. By utilizing these breeds, Tai Ping guarantees superior standards for design, quality, and performance.

Tai Ping offers a range of spun wool yarns for intricate textures and patterns, from very thin single-plies to thicker, multi-ply yarns. Additionally, wool lacet and felted Berber wools enhance Tai Ping's creative options.

Wool's inherent resilience includes mechanical strength, anti-soiling properties, and flame resistance, ensuring longevity and a luxurious appearance. Rich in lanolin, wool fibres remain smooth, lustrous, and water-resistant, with a softer texture and extended lifespan. Lanolin also provides antimicrobial properties, keeping wool fresher for longer, making it ideal for bespoke carpeting.

Key features of New Zealand Wool:

- Excellent wear resistance and compression recovery

- Low flammability, naturally self-extinguishing

- Ease of cleaning and maintenance

- Sustainable and rapidly renewable material

Transportation / Carbon Footprint

As a multinational company, Tai Ping implements processes to reduce the carbon footprint created through transportation. These include the consolidation of shipments, the reduction of heavy crating and wrapping materials and the elimination of extraneous journeys. In addition, Tai Ping has created regional production facilities in the US, Europe and Asia to improve proximity to market.

Workplace Conditions

Tai Ping commissions independent annual audits of its Xiamen artisan workshop in order to assess labour, wages and working hours, health and safety, management systems, environment and other areas affecting workers. Protective garments and safety procedures are rigorously enforced.

Tai Ping's Workplace Conditions Assessment in 2019 resulted in an overall facility score of 94% versus a global industry average of 79%. The health and safety score was 93% versus an industry average of 78% and the overall working environment achieved a perfect score of 100%, far exceeding the industry average of 81%.

Unlike many companies producing high end floor coverings, Tai Ping’s workshop received a perfect score of 100% on labour practices, based on a rigorous assessment of policies and procedure to safeguard against child labour, discrimination, harassment, abuse, forced labour and other unacceptable conditions.

Tai Ping is 100% compliant with all labour laws and all employees working in the Xiamen artisan workshop have signed employment contracts with working hours and overtime strictly regulated. In addition, free housing, free transportation to and from work, free daily meals and an educational programme is available to all factory workers. Tai Ping also contributes to China’s social security system on behalf of employees to support pension funds, medical insurance, industrial injury insurance, unemployment insurance and maternity insurance.

Child Labour Protections

Tai Ping adheres to all laws aimed at preventing child labour including the Chinese Labour Law, the Law on the Protection of Women’s Rights and Interests, the Law on the Protection of Minors, Regulations on the Prohibition of Child Labour and the Notice on the Prohibition of Child Labour. This also applies to International treaties like the U.N.’s Convention on the Rights of the Child and the International Labour Organization’s Minimum Age Convention.

Certifications & Guidance

This dynamic and regularly updated resource page serves as a central hub for Tai Ping's certifications, corporate social responsibility (CSR) initiatives, sustainability efforts, product guidance, and compliance standards. It provides a comprehensive collection of official documents, statements, and guidelines to support transparency and inform clients and stakeholders.

Explore our commitment to sustainability, corporate social responsibility, and compliance. Download essential certifications, declarations, and reports that highlight our dedication to environmentally and socially responsible practices